Our Production

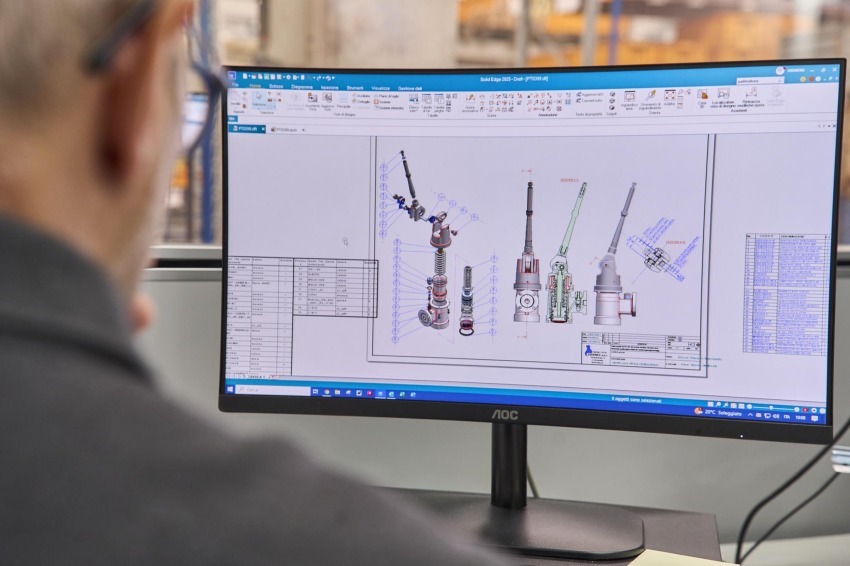

Technical design

The strength of our company in based on the research and creation of specific, customized products to meet all of our customers' requests.

Our technical office is the beating heart of the entire production system, using modern computer tools (CAD-CAM) and the latest-generation measuring machines to support and assist clients through every phase of project development.

Metal Stamping

We have always collaborated with qualified suppliers using a production technique where raw materials are shaped using modern machinery.

In recent years we have also partnered with a company of this sector, ensuring very high levels of quality and efficiency during the process.

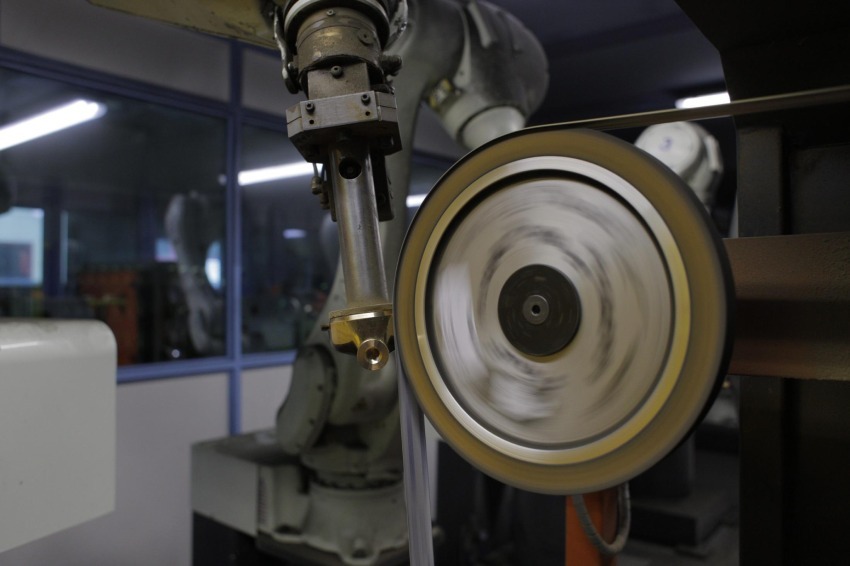

Machining

Cleaning and CAST Chrome Plating

This production process is essential for our products. Our 15 fully-robotized islands are able to daily produce thousands of pieces with extreme reliability and quality.

With the new standards and certifications achieved, galvanic treatments have become fundamental, actually we have registered our certified chrome plating CAST (CONDOR ALIMENTARY SURFACE TREATMENT) certified chrome plating which is applied to all our products.

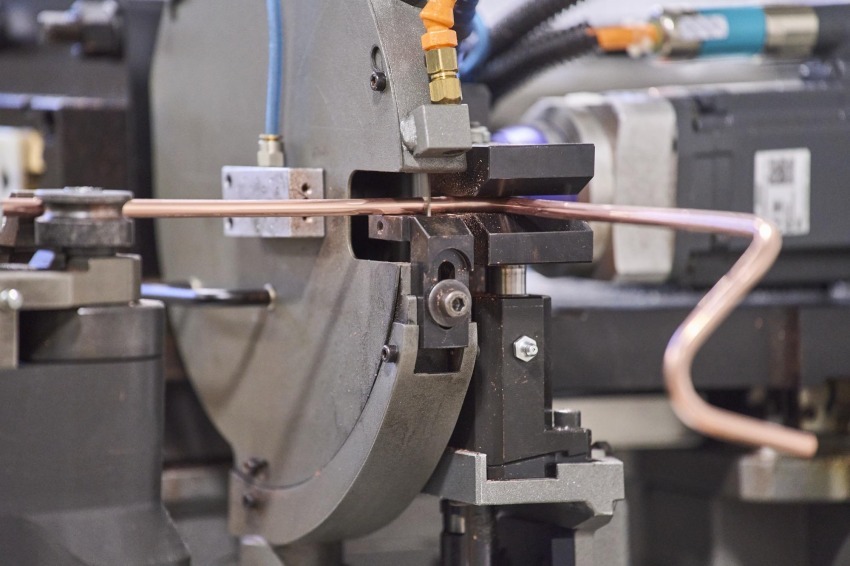

Bending and Soldering

An entire department is equipped with numerous machines that bend and curve tubes, producing approximately two hundred thousand tubes per month with customized shapes and geometries for each customer.

The main alloys used are copper, brass, and stainless steel.

By using various types of soldering (manual, induction, TIG, braze welding) and automatic welding machines, the bent and curved tubes are joint with various small parts we internally produce in order to fully satisfy quality and quantities production requires.

Assembly and Logistics

Each component produced within our supply chain is stored in the finished goods warehouse, which is synced with our management software via handheld devices.

In addition to standard shelving, our facilities also feature automated vertical warehouses to ensure greater flexibility in managing orders and shipments.

Semiautomatic and automatic assembly lines assemble thousands of items daily, having them ready for shipment to the customer.

Contact us and we will create your product together

Our technical team will assist you from design to delivery of the finished component.